How Beneficial Is The Closed Loop Extractor?

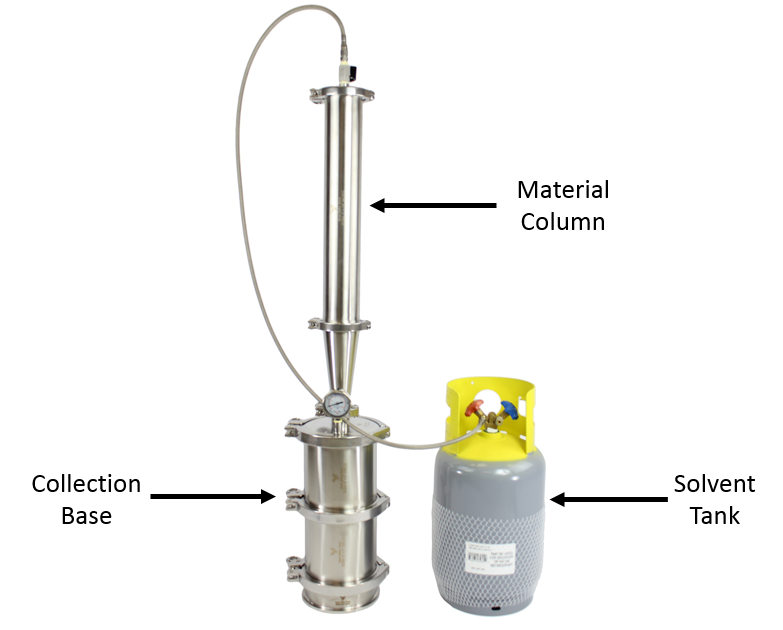

This closed loop extraction is a unique method for extracting cannabinoids from the cannabinoid

plant material. This type of Closed Loop Extractor uses the hydrocarbon solvent for extraction

purposes. This is possible when it is done in a closed loop without any contact with the air. Thus

the extraction of the cannabinoids like the CBD, THC and terpenes are possible here for the

users. This is not the only method for the extraction of cannabis alone, as this is good for

extracting essential oils for food or cosmetic items. Thus this extractor will greatly benefit the

users when they use it in various industries.

What kind of solvents is used?

Hydro carbon solvents are always the best for extracting cannabinoids or essential oils using this

Closed Loop Extractor. The extractor will be useful for creating various cannabis concentrates

like crumble, live resin, shatter, etc. Therefore this kind of extraction method is safe as the

hydrocarbon solvent that is present in it will not react to the air that is present outside. This kind

of closed loop will be useful for better extraction as the open loop will cause only the explosion

mostly. Therefore, when you want to remove cannabinoid solvents, it is time to buy the best

closed loop extractor from the top company. The solvents of the hydrocarbon like butane,

propane or a combination of both will be good to use in the closed loop system. The combination

of propane and butane will be useful and effective for extracting the solvents from the Closed

Loop Extractor. The solvents maintain a low boiling point, so the concentrates are completely

purged from the solvent, and then they are heated using the oven. Thus the extraction of the

cannabinoid solvent or even the essential oil is possible through proper refining.

What is special about this closed loop extractor?

The advantages of preferring the closed loop extractor when compared to the open loop for

cannabis or essential oil extraction are as follows.

Since the closed loop extractor is operated by OSHA standards, it is more convenient for the

industries. The reason is that this closed loop will occur in the closed vessels, and that will not

allow the hydrocarbon solvents like propane, butane and others to get into contact with the air.

Thus the solvent will be in the closed loop, which is the good one for cleaning the cannabinoid

dirt from the plant and using the extractor for refining the product. Thus it is highly safe when

you compare it with the open loop extractor.

The solvents are more effective and will be used in the proper closed-loop system without letting

the solvent evaporate. The closed loop provides the top quality extraction service where the

solubility of the cannabinoids will depend on the temperature. Thus, temperature regulation is

possible in this system, so it is more effective for use in cannabinoids or other essential oil

extraction industries.

The use of the solvents will be the same for this Closed Loop Extractor which means that the

same solvent will be used repeated times. This is more useful for businesses to use the same

solvent for the extraction continuously many times. Thus the business can save money for the

purchasing of the solvents, and that will be more beneficial.

Gives the top quality product

The extraction of the cannabinoids solvent will require proper heating and washing at regular

intervals. This is possible in this famous closed-loop system. The Closed Loop Extractor will

always be good for getting the final cannabinoids without any residue, which means that it is safe

to consume immediately. Thus the quality of the extracted product is improved high when you

choose this kind of extractor.

Working of this extractor

This is a simple closed loop extractor that uses high quality cannabinoid materials for the

extraction. The reason is that when the quality of the material is not good, then it will not provide

an effective product. The recycling of solvent for washing the cannabinoids to remove the dirt

and residues that is present. Then the proper refinement is done for the final product, and then

the solvent purge will occur. The duration of the solvent purge will vary according to the

temperature and other conditions. So the final concentrate from this closed loop is collected in

the end.

for more blog click here